Sabic plastic pellets PBT 420SE0-BK1066 Glass fiber filled Support Customized

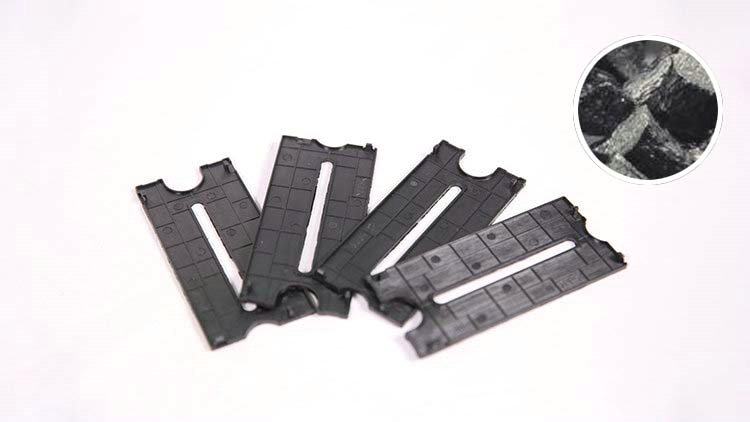

30% GR, UL94V-0/5V rated. Numerous applications; edge trimmers, food mixer motor stator and commutator, cooling fan, connectors, bobbins, switches etc

Polybutylene terephthalate (English name: polybutylene terephthalate (PBT for short), belonging to the polyester series, is a kind of opalescent translucent to opaque crystalline thermoplastic polyester resin made by polycondensation of 1.4-pbt butylene glycol with terephthalic acid (PTA) or terephthalate (DMT) and through mixing process. Together with PET, it is collectively referred to as thermoplastic polyester or saturated polyester.

a. Mechanical properties: high strength, fatigue resistance, dimensional stability, and small creep (with little change under high temperature conditions);

b. Heat aging resistance: The enhanced UL temperature index reaches 120~140 ℃ (outdoor long-term aging resistance is also good);

c. Solvent resistance: no stress cracking;

d. Water stability: PBT is not easily decomposed when exposed to water;

e. Electrical performance:

1. Insulation performance: Excellent (able to maintain stable electrical performance even in damp and high temperatures, making it an ideal material for manufacturing electronic and electrical parts);

2. Dielectric coefficient: 3.0-3.2;

3. Arc resistance: 120s

f. Molding processability: ordinary equipment injection molding or extrusion molding. Due to its fast crystallization speed, good fluidity, and lower mold temperature requirements compared to other engineering plastics. When processing thin-walled parts, it only takes a few seconds, and for large components, it only takes 40-60 seconds.

2. The application of PBT (usually referring to modified varieties);

a. Electronic appliances: connectors, switch parts, household appliances, accessory parts, small electric covers or (heat resistance, flame retardancy, electrical insulation, forming and processing properties);

b. Automobile:

1. External components: mainly including corner grille, engine heat release hole cover, etc;

2. Internal components: mainly including endoscopic braces, wiper brackets, and control system valves;

3. Automotive electrical components: automotive ignition coil twisted tubes and various electrical connectors, etc.

(The number of PBTs used in automobiles is not as high as that of nylon, polycarbonate, and paraformaldehyde, but with the emergence of low warpage PBTs, they will inevitably be more applied in automotive components in the future.)

c. Mechanical equipment: Belt drive shaft of video tape recorder, electronic computer cover, mercury lampshade, electric iron cover, baking machine parts, as well as a large number of gears, cams, buttons, electronic watch casing, camera parts (with heat and flame resistance requirements)

Because of its high melting point and crystallinity, low water absorption and coefficient of thermal expansion (CTE), it has excellent dimensional stability. In addition, it also has excellent electrical insulation, with minimal changes in electrical performance caused by moisture absorption and high insulation voltage& nbsp;& nbsp;

English name: polybutylene terephthalate

Specific gravity: 1.31g/cm ³

Melting point: 225~275 ℃

Water absorption rate: 0.34%

Forming shrinkage rate: 1.7~2.3%

Material performance

Excellent mechanical properties, especially with high rigidity and hardness, good heat resistance, and a hot deformation temperature of over 180 ℃. Good surface gloss performance, especially suitable for spray free electronic and electrical products with fast crystallization speed, good flowability, excellent formability, and good thermal stability. Especially with low thermal expansion rate and size shrinkage rate, it is resistant to chemicals, solvents, weather, high dielectric strength, good electrical performance, and low moisture absorption, Minimal impact on electrical and dimensional stability

Forming performance

1 PBT has low hygroscopicity, but is sensitive to moisture at high temperatures. During molding and processing, PBT molecules can degrade, darken their color, and cause surface blemishes. Therefore, drying treatment is usually recommended.

2 PBT melt has excellent flowability, making it easy to form thin-walled and complex shaped products. However, attention should be paid to mold overflow and nozzle salivation.

3 PBT has a significant melting point, and when the temperature rises above the melting point, its fluidity will suddenly increase, which is particularly noteworthy.

The processing range of 4 PBT molding is relatively narrow, and it crystallizes quickly during cooling. In addition, it has good flowability, making it particularly suitable for rapid injection.

5 PBT has a large shrinkage rate and its shrinkage range, and the difference in shrinkage rate in different directions is more significant than other plastics.

Application

Hot products

Production Process

6 Trustworthy Advantages

Certificate

Company Profile

Guangzhou Huaxiu Plastic Co., Ltd. is an authorized distributor of Sabic (Saudi Basic Industry) engineering plastics in the South China region. It has been focusing on Sabic engineering plastics for ten years and has been focusing on four major fields: electronic and electrical, medical, automotive parts, and communication equipment, covering various fields such as aviation, construction, environmental protection, and packaging. It is one of the most powerful Sabic material suppliers in South China

Guangzhou Huaxiu Plastic Co., Ltd. was established in 2009 and has been committed to exploring the market of SABIC materials in the South China region for many years. It is a contracted distributor of SABIC in the South China region.

Guangzhou Huaxiu Plastic Co., Ltd. has warehouses in the bonded areas of Guangzhou, Dongguan, and Shenzhen, responding quickly to customer needs. Support transactions in RMB, Hong Kong dollars, and US dollars.

Guangzhou Huaxiu Plastic Co., Ltd. has been focusing on SABIC engineering plastics for more than ten years, with a professional service team that provides a series of assistance from material identification, mold design, molding and processing, and can provide customers with high-quality SABIC material solutions。