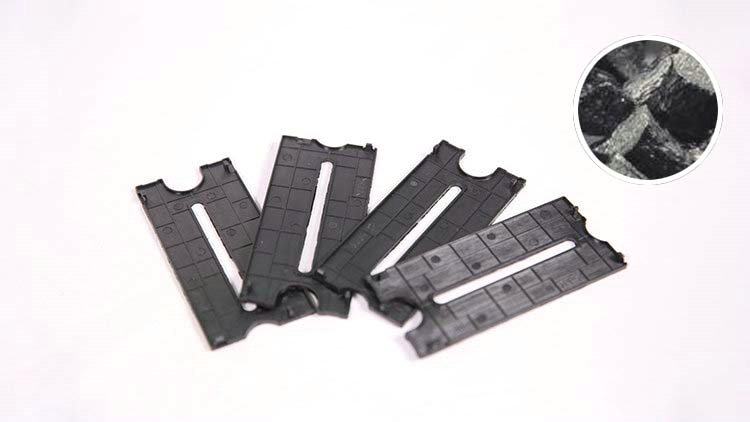

Flame retardant grade PPO SE1X-701 high temperature resistant electronic and electrical components raw materials

PPE+PS blend. Unfilled. Non-brominated, non-chlorinated FR system. UL94 V1, UL746C F1. Dielectric strength. Suitable for E/E market indoor/outdoor applications.

Forming performance

1. Non crystalline material with low moisture absorption.

2. Poor fluidity, similar to Newtonian fluid, the viscosity is sensitive to temperature, and the product thickness is generally more than 0.8mm. Extremely easy to decompose, producing corrosive gases during decomposition. The molding temperature should be strictly controlled, the mold should be heated, and the pouring system should have low resistance to material flow.

3. The water absorption rate of polyphenylene ether is very low by about 0.06%, but a small amount of water can cause the surface of the product to appear unsmooth phenomena such as silver threads. It is best to dry it, and the temperature should not be higher than 150 degrees, otherwise the color will change.

4. The molding temperature of polyphenylene ether is 280-330 degrees, and the molding temperature of modified polyphenylene ether is 260-285 degrees.

Advantages of Noryl PPO:

1. It is a white particle. Good overall performance, suitable for use in 120 degree steam, good electrical insulation, low water absorption, but prone to stress cracking. Modified polyphenylene ether can eliminate stress cracking.

2. It has outstanding electrical insulation and water resistance, and good dimensional stability. Its dielectric properties rank first among plastics.

3. It has high heat resistance, with a glass transition temperature of 211 degrees Celsius and a melting point of 268 degrees Celsius. When heated to 330 degrees Celsius, it tends to decompose. The higher the content of PPO, the better its heat resistance, and the heat deformation temperature can reach 190 degrees Celsius.

4. Good flame retardancy, self extinguishing properties, and moderate flammability when mixed with HIPS. Lightweight and non-toxic, it can be used in the food and drug industries. Poor optical rotation resistance and discoloration after prolonged use in sunlight.

Application

Hot products

Production Process

6 Trustworthy Advantages

Certificate

Company Profile

Guangzhou Huaxiu Plastic Co., Ltd. is an authorized distributor of Sabic (Saudi Basic Industry) engineering plastics in the South China region. It has been focusing on Sabic engineering plastics for ten years and has been focusing on four major fields: electronic and electrical, medical, automotive parts, and communication equipment, covering various fields such as aviation, construction, environmental protection, and packaging. It is one of the most powerful Sabic material suppliers in South China

Guangzhou Huaxiu Plastic Co., Ltd. was established in 2009 and has been committed to exploring the market of SABIC materials in the South China region for many years. It is a contracted distributor of SABIC in the South China region.

Guangzhou Huaxiu Plastic Co., Ltd. has warehouses in the bonded areas of Guangzhou, Dongguan, and Shenzhen, responding quickly to customer needs. Support transactions in RMB, Hong Kong dollars, and US dollars.

Guangzhou Huaxiu Plastic Co., Ltd. has been focusing on SABIC engineering plastics for more than ten years, with a professional service team that provides a series of assistance from material identification, mold design, molding and processing, and can provide customers with high-quality SABIC material solutions。