Sabic plastic pellets PC EXL1414-BK1A068 Support Sample Factory Supply

Impact resistant, flame retardant, transparent, heat-resistant, and easy to form.

Transparent, semi transparent, opaque, color selectable, etc

PC is a colorless, transparent and indefinite thermoplastic resin. Bisphenol A and diphenyl carbonate are synthesized by transesterification and polycondensation.

Density: 1.18-1.22g/cm へ 3, with 10% GF added, an increase of 0.08g/cm へ 3

Heat deformation temperature: 135C, with GF added, it can increase by 10C

Melting point: not fixed, forming temperature: 230-320 ℃

Shrinkage rate: 0.5-0.7%, with GF added, the shrinkage rate will decrease

Absorption rate, 23 ℃ 0.35%, drying material 120 ℃, 3-4 hours

English name: Polycarbonate

Specific gravity: 1.18-1.20 g/cm3

Molding shrinkage rate: 0.5-0.8%

Forming temperature: 230-320 ℃

Drying conditions: 110-120 ℃ for 8 hours

Material performance

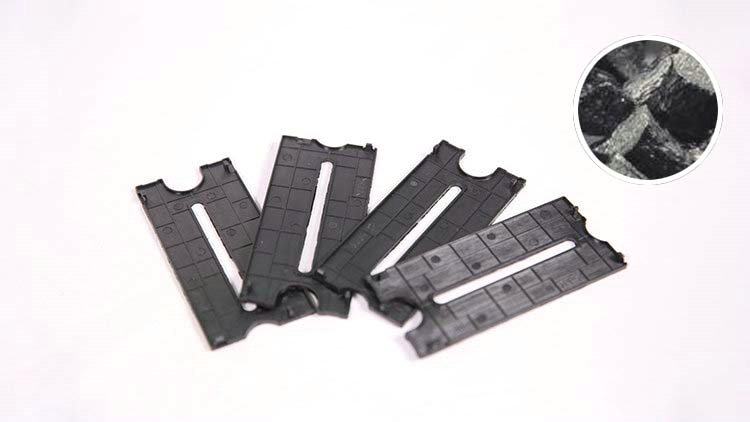

High impact strength, good dimensional stability, colorless and transparent, good coloring, good electrical insulation, corrosion resistance, and wear resistance, but poor self-lubrication, stress cracking tendency, easy hydrolysis at high temperatures, and poor compatibility with other resins.

Suitable for making insulated transparent parts and impact resistant parts for small instrument parts.

Forming performance

1. Amorphous material, good thermal stability, wide forming temperature range, and poor flowability. Low moisture absorption, but sensitive to water and requires drying treatment. The forming shrinkage rate is small, which is prone to melting cracking and stress concentration. Therefore, the forming conditions should be strictly controlled, and the plastic parts must undergo annealing treatment.

2. For plastic parts with high melting temperature, high viscosity, and greater than 200g, it is advisable to use a heated extension nozzle.

3. The cooling speed is fast, and the mold pouring system should follow the principle of being thick and short. It is recommended to set up a cold material well, the gate should be large, and the mold should be heated.

4. If the material temperature is too low, it will cause material shortage, resulting in a dull plastic part. If the material temperature is too high, it is easy to overflow the edge, and the plastic part will bubble. When the mold temperature is low, the shrinkage rate, elongation rate, and impact strength are high, while the bending, compressive, and tensile strength are low. When the mold temperature exceeds 120 degrees, the plastic part cools slowly and is prone to deformation and sticking to the mold.

Application

Hot products

Production Process

6 Trustworthy Advantages

Certificate

Company Profile

Guangzhou Huaxiu Plastic Co., Ltd. is an authorized distributor of Sabic (Saudi Basic Industry) engineering plastics in the South China region. It has been focusing on Sabic engineering plastics for ten years and has been focusing on four major fields: electronic and electrical, medical, automotive parts, and communication equipment, covering various fields such as aviation, construction, environmental protection, and packaging. It is one of the most powerful Sabic material suppliers in South China

Guangzhou Huaxiu Plastic Co., Ltd. was established in 2009 and has been committed to exploring the market of SABIC materials in the South China region for many years. It is a contracted distributor of SABIC in the South China region.

Guangzhou Huaxiu Plastic Co., Ltd. has warehouses in the bonded areas of Guangzhou, Dongguan, and Shenzhen, responding quickly to customer needs. Support transactions in RMB, Hong Kong dollars, and US dollars.

Guangzhou Huaxiu Plastic Co., Ltd. has been focusing on SABIC engineering plastics for more than ten years, with a professional service team that provides a series of assistance from material identification, mold design, molding and processing, and can provide customers with high-quality SABIC material solutions。